Samson Machine Solves Construction Problem

John Dennigan, a construction project manager, encountered a building problem that could only be solved with a Samson machine. "We recently constructed two industrial buildings that were designed with curved walls in the front," he explained. "We framed one of the buildings the old fashioned way." This involved sawing numerous notches into straight metal channels and bending them at each notch to create the curve. The framers ran these channels horizontally at the top and bottom of the wall and stood straight metal studs vertically between them. To get the shape right they had to carefully measure and draw on the floor and use levels at every stud to adjust the top with a lot of trial and error. They had to make several little plates that they drilled and screwed to the channels at each notch to hold them in place. "The whole process was very time-consuming and costly," said Dennigan.

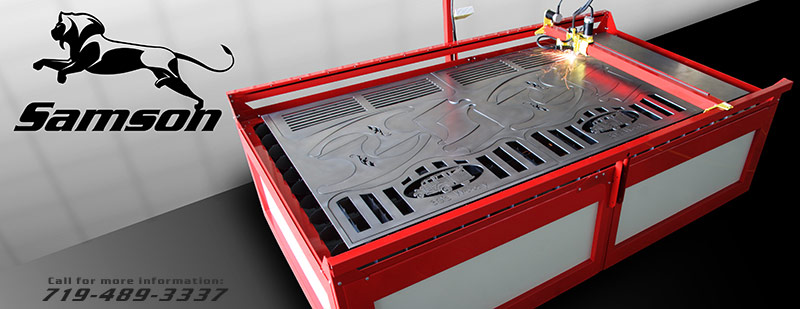

The other building was even more difficult because the curved wall was longer and it had more windows. "We tried to make the curved pieces the same way, but we couldn't get the shapes right," said Dennigan. Then he got a Samson machine and used the software to draw long, curved plates that exactly matched the radius in the prints. "It was easy to set up and run the system and cut the plates out," he said. They used the plates for the walls, including the tops and bottoms of the windows. "The wall went together much more quickly than the other building. It was perfectly shaped and turned out much stronger. Without our Samson machine, Im not sure we would have been able to finish the job correctly."

Later Dennigan was also able to build a sign for one of the buildings. "We got a copy of the company logo and loaded it into the software. We scaled it to 14 feet long and cut it out of 1/4-inch plate. Then we mounted it on the wall. It was simple!"